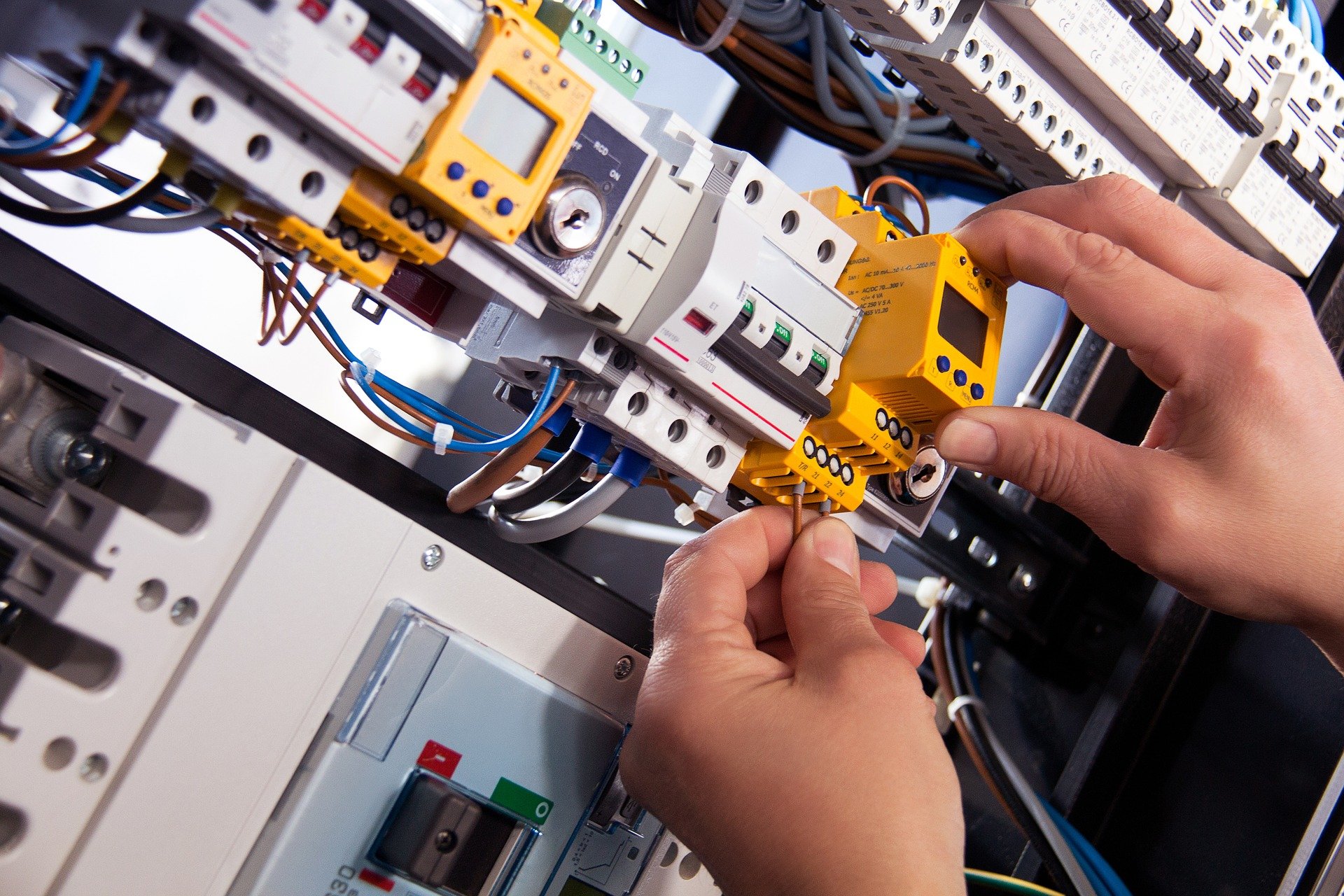

Protective devices used in electrical installations, RCDs are deisgned to quickly break electrical circuits, thus preventing the user from any serious harm as a result of electric shock. There are a few different types of RCD, from plug in types, to other options that are able to sit on fuse boards or boxes.

Here, we take a closer look at the different types of RCD, their purposes and safety features, so as to offer further understanding and protection when planning an electrical installation.

Residual Current Devices (RCDs)

In essence, an RCD is a protective, life-saving device, used primarily in electrical installations. Otherwise known as a ‘Residual Current Device’, an RCD is designed to prevent you from receiving a potentially fatal electric shock if you were to touch an exposed wire. RCDs provide a level of protection that ordinary fuses and circuit-breakers fail to offer.

What Do They Do?

RCDs are designed to check that the current flowing through the live wire is equal to the current flowing back through the second part of the circuit, aka the neutral wire. As a sensitive safety device that switches off electricity automatically if there is a fault, an RCD is designed to protect against the risks of electrocution and fire caused by earth faults. For example, if you cut through the cable when mowing the lawn and accidentally touched the exposed live wires, you’d be protected from receiving an electric shock.

Constantly monitoring the flow of electricity, an RCD is able to detect when electricity is flowing down an unintended path, such as through a person who has interfered with a live wire. If this were to occur, an RCD would recognise the issue immediately, switching the circuit off quickly, reducing the risk of death or severe injury.

How Do They Work?

Inside every RCD is an iron core. When electricity flows from a live cable into an RCD, it passes through the switchgear and a coil wrapped around the core. Once the electricity moves around the coil, it generates a magnetic field. The current that then flows back into the RCD from the neutral cables passes through a coil wired in opposition to the live wire. This creates two opposing magnetic fields. With the current returning through the neutral wire providing the same current that was supplied, the two opposing magnetic fields will be equal and cancel eachother out. With no magnetic field overall, nothing will happen to the switchgear. The current will continue to run around the appliance as intended.

Should there be a fault in an appliance, electricity can leak into the ground. When this happens, the current supplying the device will remain the same. Thus, the magnetic field in the first coil would still be the same too. However, if electricity is leaking away, less current would return to the neutral coil, leading to an imbalance between the two magnetic fields. This triggers the switchgear. The switchgear possesses an iron panel attracted to the iron core in this instance, breaking the circuit.

A reset button is then pressed to push the circuit back into place.

Types of RCDs

RCDs can help protect you from electric shock in potentially dangerous areas like bathrooms and gardens, and there are various types of RCDs that can be used to make sure you are always as safe as possible. Let’s take a closer look at the main types of RCD:

Type AC

These RCDs are on hand to detect alternating currents. They are suitable for general use and operate alongside the vast majority of applications.

Type A

These RCDs detect residual current as well as alternating. Specifically intended to be used for single phase class 1 electronic loads.

Type F

These RCDs are designed for circuit protection where single variable speed drivers could be used. They also offer detection for residual and alternating currents.

Type B

These RCDs are intended to be used for loads with three-phase rectifiers, such as variable speed drives, PV system, EV charging stations and medical equipment.

Fixed RCDs

Installed in the fusebox, a fixed RCD will provide strong levels of protection to an individual or group of circuits. Offering the highest level of protection, a fixed RCD shields all the wiring and sockets on an electrical circuit as well as any connected appliances.

Socket-Outlet RCDs

These are specially designed socket-outlets with an RCD already built-in, in place of a standard socket-outlet. This type of RCD provides some protection against the threat of electric shock, but only to the person who has come into contact with the equipment.

Portable RCDs

Portable RCDs can be plugged into any standard socket-outlet. Useful when neither fixed nor socket-outlet RCDs are available, they are also only able to protect the person who has come into contact with the electrical equipment.

How do I check whether I already have fixed RCD protection?

To check if you have fixed RCD protection, go to your consumer unit and check if there is a device with a pushbutton marked ‘T’ or ‘Test’. This ‘test’ button is part of an RCD. If an RCD is fitted, there should also be a label on or near the consumer unit stating ‘test quarterly’.

Testing RCDs

Testing your RCDs at regular intervals is pivotal to ensuring you have fitted them into your property or circuit board correctly. Fortunately, RCDs are easily testable and simple to reset. Each RCD will be fitted with a test button and a reset button. The test button creates a safe, small leakage, whilst the reset button reconnects the conductors once a fault has been cleared.

Testing an RCD: Step by Step Guide

- Plug a small lamp appliance into a socket and make sure it is working. Leave it turned on.

- Ensure that the electricity is connected to the RCD securely and that the main switch is in ‘on.’

- Turn off all of your other electronic appliances such as televisions and radios.

- Press the test button on your RCD, but do not hold your finger down on the test button. At this point, your RCD should operate, ie, turn off the appliance. If it does not operate, you should have it checked by a professional.

- After pressing the test button, and the RCDs have turned off, check that your small lamp is now off. You’ll need to move the lamp around several power points and ensure that it does not turn on when plugged into any of them.

Once you have completed your testing, you can turn your RCD back on and check that the lamp works when plugged back into a power source

Costs

On average, a typical plug-in RCD can cost as little as £10, but fixed RCDs will cost more. Installation costs will vary, so we recommend getting several quotes before proceeding.

Reliability

Fixed RCDs have been found to be 97% reliable, with room for improvement, should they be tested regularly. With RCD protection, the risk of electric shock is reduced, and your home is far safer from the risk caused by faulty wiring or appliances. However, although RCD protection does reduce the overall risk of death or severe injury, it does not reduce the need to be careful. Should you find a fault with your wiring, or appliance, you must stop using it immediately and contact an electrician.

Ian Hobbs Technical Services LTD – Multi-Disciplined Installation and Service Provider

Here at Ian Hobbs Technical Services Ltd, we offer commercial installations, maintenance and repairs.

From high-quality air conditioning to refrigeration and electrical services, we’re available for clients across Bristol, Bath and the South West. Find out more about our range of services and get tailored advice and guidance from our team. If you have any further questions about cold storage units, or if you’d like to know about any of our other electrical, renewable, air conditioning, or plumbing and heating services, then don’t hesitate to get in touch today.

01761 414 356

01761 414 356