In the food industry, maintaining proper storage conditions is vital for product quality, regulatory compliance, and operational efficiency. Walk-in cold rooms have become an essential solution for businesses ranging from restaurants and catering companies to food manufacturers and wholesalers. These systems provide controlled environments for perishable goods, helping prevent spoilage and ensure freshness. In this article, we explore the benefits of walk-in cold rooms, key considerations during cold room installation, and how partnering with professional cold room suppliers and commercial refrigeration engineers like Ian Hobbs Technical Services can deliver tailored solutions for your business.

Why Walk-In Cold Rooms Matter for Food Storage

Walk-in cold rooms offer businesses a reliable way to store perishable items at consistent temperatures. Unlike standard refrigeration units, walk-in cold rooms can accommodate large volumes of stock, making them ideal for commercial kitchens, food factories, and supermarkets. Consistent temperature control prevents spoilage, reduces waste, and protects both staff and customers. Additionally, modern cold rooms are energy-efficient, helping businesses reduce running costs while maintaining high-performance storage.

The versatility of walk-in cold rooms also makes them suitable for a wide range of applications. Whether storing fresh produce, dairy, meat, or frozen products, these systems allow for careful inventory management and ensure that your products remain safe and compliant with food safety regulations.

Understanding Cold Room Installation

Cold room installation is a specialised process that requires careful planning, precision, and technical knowledge. Before installation, a detailed assessment of your storage needs is crucial. This includes considering the types of products to be stored, the required volume, and the available space. At Ian Hobbs, we ensure that all elements of our professional cold rooms, from design to installation, are tailored to your operational requirements.

The installation process typically involves designing the layout, selecting high-quality insulation, installing refrigeration systems, and fitting essential accessories such as insulated doors, shelving, and temperature monitoring systems. By carefully planning each step, businesses can achieve maximum efficiency, reliability, and compliance with food safety regulations.

Why Work with Professional Cold Room Suppliers

Working with experienced cold room manufacturers and suppliers ensures a high-quality, reliable installation. Trusted providers offer guidance throughout the process, ensuring your system meets both your operational and regulatory requirements. Key advantages of partnering with a professional supplier include:

- Tailored designs that meet specific business requirements

- Expert advice on refrigeration systems, insulation, and controls

- Compliance with food safety standards and regulations

- Long-term support and maintenance packages

These benefits ensure your walk-in cold room delivers consistent performance, reduces the risk of downtime, and maintains product quality over time.

Benefits of Walk-In Cold Rooms

Investing in a walk-in cold room provides a range of benefits for businesses in the food industry, improving not only storage capabilities but also overall operational efficiency. One of the primary advantages is energy efficiency and cost savings. Modern cold rooms are built with high-quality insulation panels and efficient refrigeration systems, which help maintain a consistent temperature with minimal energy consumption. By reducing energy usage, businesses can lower their operating costs while also supporting environmentally friendly practices. Advanced controls and monitoring systems further optimise energy efficiency by preventing overcooling or unnecessary running of compressors.

Another key benefit is inventory management improvements. Temperature-controlled storage ensures that perishable products remain fresh for longer, reducing the risk of spoilage and food waste. Walk-in cold rooms make it easier to organise stock logically, allowing staff to rotate items according to the first-in, first-out (FIFO) principle. This not only preserves product quality but also supports better planning and supply chain management. For businesses handling large volumes of food or ingredients, such precise storage control can significantly impact profitability.

Walk-in cold rooms also enhance staff safety and workflow efficiency. By providing a dedicated space for food storage that is easy to access and properly organised, employees can work more safely and effectively. Clear layouts, shelving systems, and wide access points reduce the risk of accidents, such as slips or trips caused by overcrowded storage areas. Additionally, properly designed cold rooms enable smoother workflows during stock handling, order preparation, and cleaning operations, saving time and improving productivity across the team.

Applications Across Industries

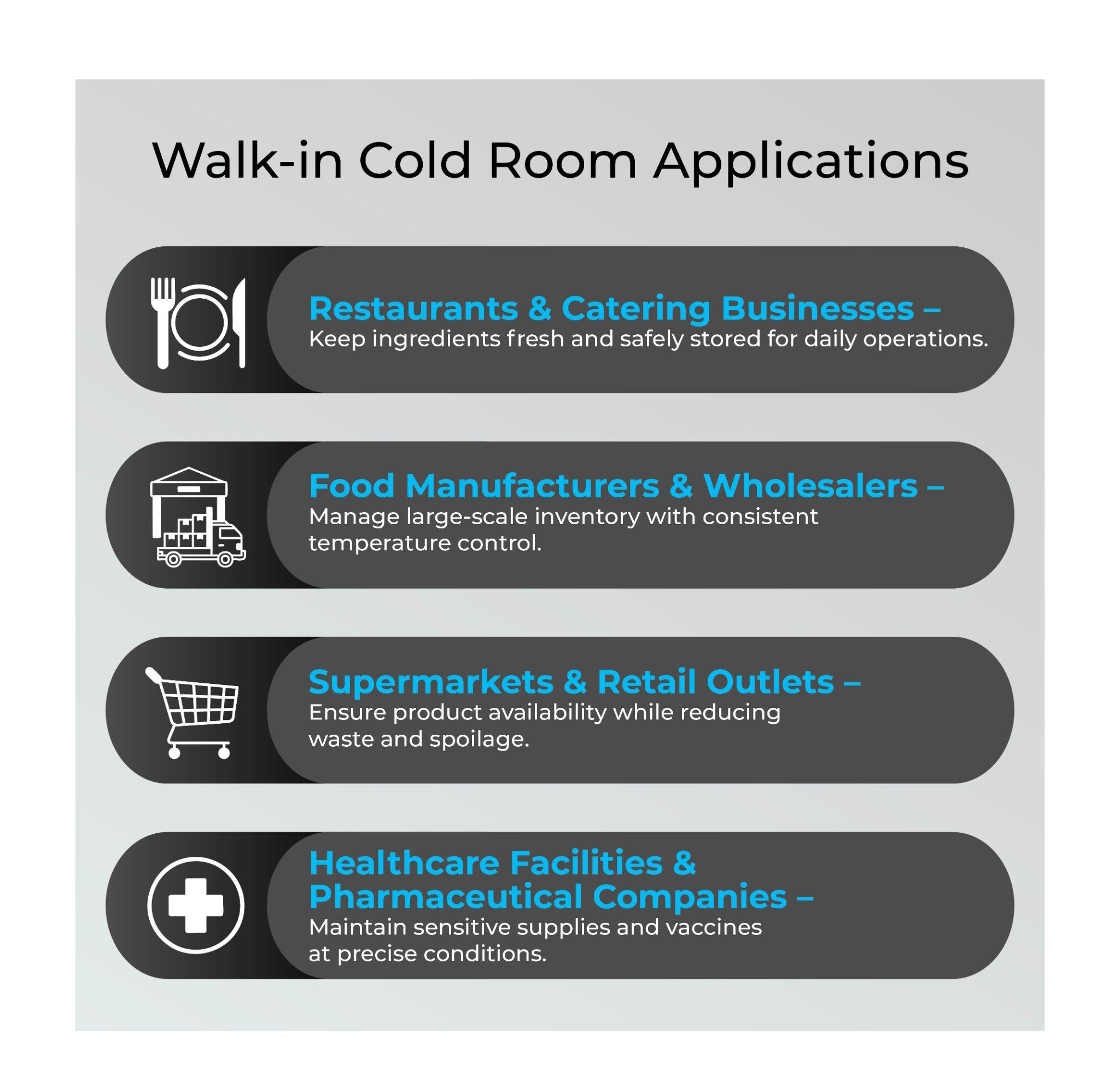

Walk-in cold rooms are highly versatile and used across a variety of industries. Restaurants and catering businesses rely on them to store fresh ingredients safely, while food manufacturers and wholesalers use large-scale cold rooms to manage inventory efficiently. Supermarkets and retail outlets depend on these systems to maintain product availability and reduce waste. Additionally, healthcare facilities and pharmaceutical companies can utilise temperature-controlled environments to store sensitive medical supplies and vaccines.

The flexibility of modular cold rooms also allows businesses to expand or reconfigure their storage as their operations grow. This adaptability makes walk-in cold rooms a smart long-term investment for businesses of all sizes.

Key Considerations When Choosing a Cold Room

Selecting the right cold room involves careful consideration of several factors. Size and capacity should reflect both current and future storage needs, while the temperature requirements depend on the type of products being stored. Modular and energy-efficient systems offer flexibility and reduce operating costs, while reliable maintenance and support services ensure consistent performance.

When designing or choosing a cold room, businesses should also consider the following factors:

- Temperature control and monitoring: Ensure consistent refrigeration for all types of perishable goods.

- Insulation quality: High-grade insulation helps maintain efficiency and reduce energy consumption.

- Accessibility and layout: Optimize storage flow and ease of access for staff.

- Regulatory compliance: Ensure the installation meets health and safety requirements.

These considerations help businesses select a cold room that maximises efficiency, safeguards

01761 414 356

01761 414 356