Many businesses, from supermarkets and restaurants to hotels and healthcare facilities, rely on commercial refrigeration systems to carry out their daily operations. Inefficient or malfunctioning fridges can have disastrous effects on these businesses, leading to loss of revenue or long periods of downtime. Professional fridge engineers play a vital role in enhancing business efficiency by maintaining refrigerators for optimal performance.

In this article, we will explore how fridge freezer engineers support businesses in enhancing business performance, including the importance of effective refrigeration, the common challenges of refrigeration, and how refrigeration engineers address them.

The Importance of Reliable Refrigeration

From preserving perishable goods to ensuring the integrity of critical materials, refrigeration is essential for the smooth operation of businesses and organisations across various industries. For many key sectors, optimal refrigeration isn’t just important, it’s necessary.

Food and Beverage Industry

Every business that involves producing or handling food for public or private consumption requires careful refrigeration. This must occur at every stage of the food supply chain, from farm to plate. Whether you are purchasing food at the supermarket, a restaurant or a hotel, it is the responsibility of the provider to ensure that perishable goods have been stored at safe temperatures not only to maintain product quality but more importantly, to ensure they are safe to eat.

In the restaurant industry, for example, ingredients need to be stored at specific temperatures to avoid bacterial growth that could lead to foodborne illnesses. Likewise, if supermarkets did not have effective refrigeration, fresh and frozen produce would spoil quickly. By maintaining optimal temperatures, efficient refrigeration systems help maximise the shelf life of perishable goods.

Healthcare Facilities

Healthcare facilities, like GP surgeries or hospitals, need effective refrigeration to safely store medications and blood reserves. Many medical substances must be stored at safe temperatures to remain stable, while others must be kept within a certain range to maintain optimal efficacy.

Blood and other medicines must be stored correctly so healthcare professionals know they will have the intended effect. For example, blood should be stored between 2°C and 6°C in a blood bank refrigerator. If blood is stored outside of this range, its oxygen-carrying ability may be reduced, and the risk of bacterial contamination is greater.

Pharmaceutical Industry

The pharmaceutical industry depends on refrigeration to ensure the proper storage and preservation of sensitive materials, including medicines, chemicals, and substances. Maintaining a consistent, controlled temperature is vital for creating a stable testing environment and for complying with strict health and safety regulations.

Any deviation in temperature, whether too high or too low, can alter the properties of chemicals, compromising their usability and consistency in experiments. In severe cases, such fluctuations can render substances hazardous, posing significant risks to workers, such as chemical burns.

Research Facilities

Research facilities work with critical assets like biological samples, DNA, and other research materials that require strict temperature regulation for preservation. Energy-efficient refrigeration systems play a key role in protecting these materials and preventing loss due to fluctuations.

A consistent and controlled temperature ensures the integrity of samples and experiments. If refrigeration systems fail, temperature variations can harm the reliability of experiments.

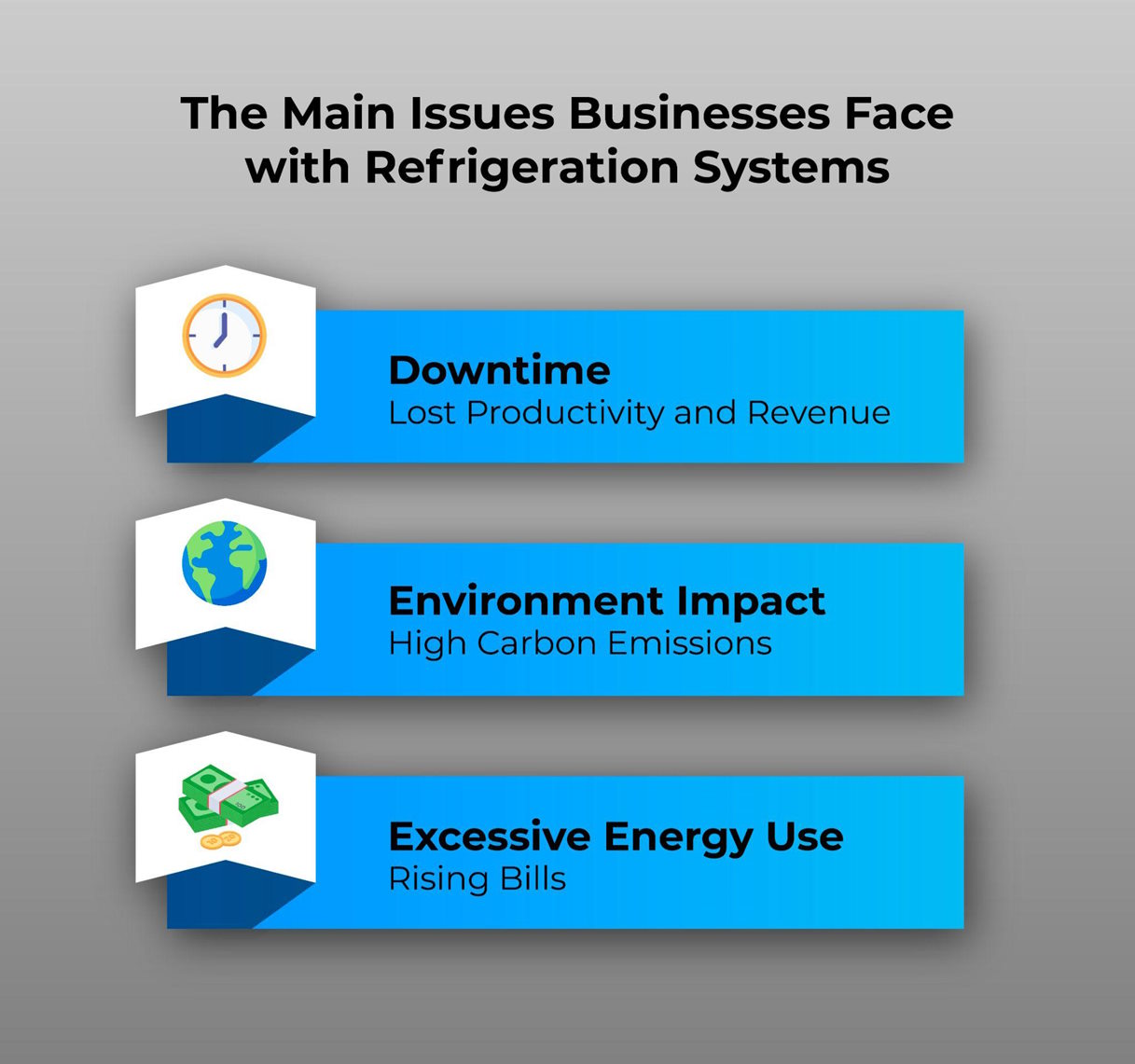

Common Challenges With Refrigeration Systems

Increased Downtime

Having a refrigeration system without an effective maintenance and care plan in place can disrupt operations and impact productivity. As mentioned previously, various industries that rely on consistent cooling, like food preparation or pharmaceuticals, may have to shut down while fridge or freezer issues are addressed.

Downtime, whether caused by a refrigeration system malfunction, component failure, or delayed maintenance, can have devastating effects on a business’s overall performance. For example, if restaurants experience fridge or freezer issues, prolonged downtime can cause perishable goods to spoil, resulting in financial losses. Serving spoiled food in a restaurant that causes illness can severely damage customer trust and prevent customers from coming back.

Environmental Impact

Outdated or poorly maintained commercial refrigeration systems have a significant environmental impact. Providing consistent cooling can use a lot of energy, resulting in high carbon dioxide emissions. Additionally, refrigeration uses refrigerants, such as hydrochlorofluorocarbons (HCFCs), a cooling fluid that absorbs heat and leaves cool air behind. These are harmful to the environment, depleting the ozone layer and contributing to global warming.

High Energy Costs

Poor energy efficiency not only has a negative impact on the environment, but it also results in high running costs. Refrigeration systems with poor energy efficiency consume more power to maintain desired temperatures, leading to higher utility bills. Inefficient components, such as outdated compressors or inadequate insulation, cause systems to work harder and longer to achieve cooling, wasting energy in the process.

Additionally, excessive energy consumption contributes to wear and tear. Energy inefficiencies can shorten the system’s lifespan and potentially increase maintenance and replacement expenses, further driving up overall running costs.

How Fridge Engineers Can Help

Refrigeration engineers play a crucial role in helping businesses improve energy efficiency by conducting regular maintenance, implementing modern technologies, and optimising system performance. These efforts make refrigeration systems perform more reliably and sustainably while reducing running costs.

Regular Maintenance

One of the key ways a business can enhance the energy efficiency of its refrigeration systems is by keeping up with its routine maintenance requirements. Fridge freezer engineers ensure a fridge is operating at peak performance by carrying out inspections to identify and address energy efficiencies. For example, worn components, a build-up of dust and debris and improper refrigerant levels can reduce energy efficiency, requiring more energy for a fridge to maintain a consistent cool temperature.

Regular maintenance also enables fridge engineers to catch minor issues early. Addressing issues promptly allows for quicker and simpler resolutions and prevents them from escalating into severe problems like total system failure, where whole system replacement may be the only option.

Energy-Efficient Equipment

Fridge engineers can help you understand which energy-efficient systems are worth the investment and handle your regular efficiency maintenance work. By using less energy, these systems minimise the strain on the National Grid and reduce the demand for electricity. This helps businesses lower their carbon emissions and contribute to a more sustainable future.

Refrigerant Management

Fridge engineers are highly knowledgeable about sustainable technologies and strategies that can be utilised to minimise environmental impact. Rather than using traditional refrigerants, fridge freezer engineers may recommend environmentally friendly refrigerant options, which are designed to protect the ozone layer and reduce climate change.

Remote Monitoring

Modern refrigeration systems can be equipped with monitoring capabilities to track energy consumption and system performance. By implementing this system and monitoring the data, refrigeration engineers can help you identify potential issues and make adjustments, ensuring your energy consumption remains optimal and avoiding energy wastage.

Compliance With Health and Safety Standards

For industries reliant on refrigeration, routine maintenance is a necessary requirement to meet UK Health and Safety Standards. Regular servicing completed by qualified fridge freezer engineers is mandated to identify and resolve issues like temperature inconsistencies or refrigerant leaks, that could cause goods to spoil or affect worker safety.

Maintenance Companies Near Me

At Ian Hobbs Technical Services, we are proud to offer a range of services that are tailored to your exact requirements. Our qualified technical services engineers have a wealth of expertise and experience when it comes to finding the right solution for your business. From refrigeration system supply or cold room design, installation, maintenance and repairs, our fridge engineers can handle your every refrigeration need.

If you are searching for ‘refrigeration maintenance companies near me’, we are here to help. Contact Ian Hobbs Technical Services to discuss your refrigeration needs with one of our helpful team members.

01761 414 356

01761 414 356