Cold room installations are essential for businesses across various industries, including food production, hospitality, and pharmaceuticals. They provide a reliable way to maintain consistent temperatures, ensuring products remain safe, fresh, and of high quality.

In this article, we’ll explore the critical role of cold room installations in ensuring optimal storage, looking at how they offer effective temperature control, preserve product integrity, and help businesses meet industry standards for storage and safety.

What Are Cold Rooms?

Cold rooms, also known as freezer rooms or walk-in freezers, are storage spaces where the temperature is artificially controlled. These walk-in fridges and freezers are specially designed to keep products at precise temperatures. They are generally set between 0°C and +10°C for chiller rooms and -18°C to -25°C for freezer rooms.

Rather than a business having multiple refrigerators, a single cold room installation can handle its cooling requirements in one space. These cold rooms create a climate-controlled environment that keeps products, whether edible or inedible, at desired temperatures for longevity and safety, preventing them from deteriorating before their shelf life.

By incorporating sophisticated refrigeration technology, walk-in cold rooms offer a higher level of temperature control, which results in fresher, better-preserved goods.

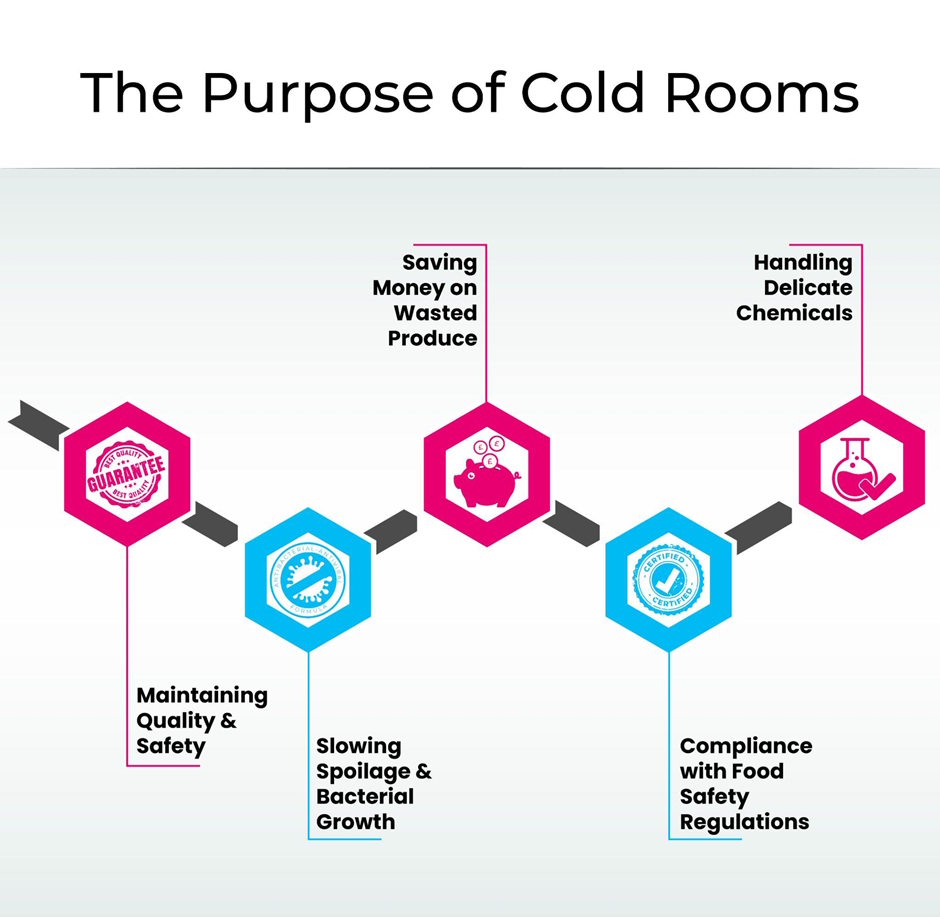

What Are Cold Rooms Used For?

Cold rooms and freezer rooms can be used to store a wide range of products across many industries. Essentially, anything that requires cool, controlled temperatures to preserve their quality and usability can be stored in either a walk-in fridge or freezer.

Food Industry

One of the primary sectors where walk-in cold rooms are paramount is the food industry. Whether for food production, packaging, or retail, these installations maintain food safety standards, ensure produce tastes great and lasts its maximum shelf life. By keeping perishable items at optimal temperatures, food businesses can minimise the losses associated with poorly refrigerated foods.

Pharmaceutical Companies

Pharmaceutical companies rely on modular cold rooms to store important medicines like vaccines. These drugs must be kept at strict temperatures to maintain their effectiveness and ensure they are safe to administer. Improper storage can render them ineffective or even dangerous. Cold rooms provide the necessary stability and reliability, ensuring pharmaceutical products remain safe for use.

Florists

Many florists also utilise cold rooms, as flowers require cool, stable conditions to retain their freshness, colour, and fragrance past their natural lifespan. Without proper refrigeration, flowers deteriorate quickly. As customers rarely want to buy flowers that are showing signs of wilting, poor refrigeration can directly impact the business’s bottom line.

Tech

Cold rooms are also an essential piece of equipment for the technology industry. Modular cold rooms can be implemented to regulate the temperature of servers and other high-powered electronic equipment, which generate a significant amount of heat. Without efficient cooling, their performance and lifespan can be rather limited. A cold room installation ensures optimal operating temperatures, preventing overheating and costly system failures.

The Benefits of Cold Room Installations

Reliable Temperature Maintenance

Cold rooms and freezer rooms maintain stable temperatures that can be adjusted to meet specific requirements. This consistency helps preserve the quality of stored goods, ensuring they remain as fresh as possible.

Additionally, even in the event of a power outage, the high level of insulation in these rooms helps retain cold temperatures for longer, reducing the risk of spoilage and minimising waste. This added protection makes cold rooms a reliable storage solution for businesses that require strict temperature control to maintain product quality and safety.

Energy Efficiency Refrigeration

Cold room installations are designed with high-quality insulation materials that improve energy efficiency by preventing temperature fluctuations and minimising energy waste. Proper insulation reduces energy consumption while maintaining stable temperatures, lowering running costs.

Most standard modular cold rooms and freezer rooms are ‘plug and play’ systems, meaning they can be connected via a standard three-pin plug for immediate use. However, for larger-scale installations, three-phase power supplies are often the more energy-efficient choice in the long run.

Customisation Options

Walk-in cold rooms can be customised to meet a business’s exact requirements, ensuring both efficiency and convenience. Custom features such as insulated doors, internal lighting, shelving, and multiple access points can be integrated into the cold room to tailor the storage to address specific needs.

Storage layouts can also be customised to facilitate FIFO (First In, First Out) stock rotation, reducing waste and ensuring older stock is used before newer items.

For specialised industries additional features, such as racks and hooks, can transform a modular cold room into a meat storage space for butchers or abattoirs. Similarly, shelving with drainage systems makes them ideal for fishmongers, while glass cold rooms provide a premium solution for displaying wines, cheeses, or other perishable products.

Improved Hygiene

Walk-in cold rooms offer a hygienic and easy-to-clean alternative to traditional refrigeration units. Their spacious interiors allow for more thorough cleaning, reducing the risk of bacteria build-up and ensuring compliance with food safety regulations.

Many cold rooms feature smooth, non-porous surfaces that resist mould and bacterial growth. Additionally, integrated drainage systems allow for simple washing and disinfection, creating a sanitary and controlled environment for perishable goods.

Long-term Cost Savings

The initial cost of installing a cold room varies significantly based on factors such as size and cooling requirements. For instance, a small restaurant will have lower installation costs compared to a large food packaging facility that requires greater cooling capacity. However, regardless of size, walk-in cold rooms offer a cost-effective long-term solution.

With proper maintenance, a modular cold room can last between 10 and 20 years, ensuring a strong return on investment. Over time, the energy efficiency and reliability of a well-maintained cold room can lead to significant cost savings, making it a worthwhile investment for businesses of all sizes.

Ian Hobbs Technical Services

At Ian Hobbs Technical Services we’re a leading walk-in cold room installer in Bath and across the South West. Our team of fridge freezer engineers provides tailored solutions, ensuring efficient and reliable temperature-controlled environments for businesses in a variety of industries.

With extensive experience in modular cold room design, we offer cost-effective, innovative freezer room and walk-in cold room solutions that maximise energy efficiency and storage capacity.

To learn more about cold room installations and let us help you create the perfect temperature-controlled storage solution for your business, contact the fridge freezer engineers at Ian Hobbs Technical Services today!

01761 414 356

01761 414 356